This article is an English translation of a Foovo article, published with permission from Foovo.

The research lab of Shoji Takeuchi at the University of Tokyo, which is developing cultured steak, announced in August this year that it had successfully created a piece of cultured meat measuring 5.5cm x 4cm x 1.5cm.

On the 10th of this month, during the 13th International Cellular Agriculture Conference (Cultured Food Research Society), Dr. Ai Shima, a project assistant professor at the Graduate School of Information Science and Technology at the University of Tokyo, presented the recent achievements and ongoing efforts in cultured meat research.

Creating Cultured Meat size of 5.5 cm x 4 cm x 1.5 cm Using a Bottom-Up Method

To create a thick cultured steak, it is necessary to align muscle fibers throughout the tissue and reproduce the tissue structure of skeletal muscles as seen in the body. However, when attempting to create thick tissue, the center of the tissue is prone to necrosis. Therefore, it is necessary to supply oxygen and nutrients to prevent the cells from dying.

The Takeuchi Lab is using two strategies to develop cultured steak: a bottom-up micro-module stacking method and a top-down perfusion culture method using a hollow fiber bioreactor.

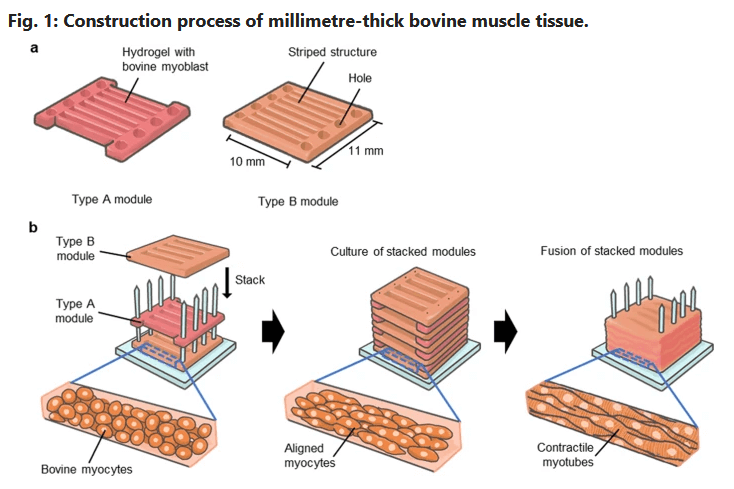

In the micro-module stacking method, two types of sheet-like modules are stacked in a bottom-up fashion, similar to layering a mille-feuille. These modules are made by pouring bovine myoblasts and collagen into a mold, forming sheet-like structures with slits to enhance oxygen permeability. The modules are stacked onto anchors, fixed at both ends, and cultured to allow the formation of muscle fibers in one direction within the tissue.

After stacking 40 layers and culturing them for one week, they succeeded in creating cultured meat measuring 8mm x 10mm x 7mm. This achievement was announced in 2021, marking the first step toward the development of cultured steak.

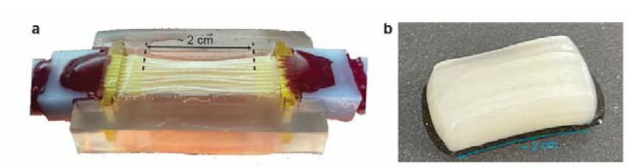

The version created this year was even larger, measuring 5.5cm x 4cm x 1.5cm, and contained not only myoblasts but also bovine adipose tissue.

Professor Takeuchi commented on this achievement on LinkedIn, saying, “Our cultured beef with fat is finally here—a 5.5 cm × 4 cm × 1.5 cm piece of structured meat. We’re not stopping here—there’s so much more to come as we continue to advance.”

Development of Cultured Meat Using a Top-Down Approach with Hollow Fibers

While the module stacking method enabled the creation of thick cultured meat, stacking 40 modules one by one requires specialized techniques.

Therefore, the next approach was a top-down strategy.

Similar to the process inside an animal’s body, the idea is to create artificial blood vessels and perform perfusion culture to generate large tissue from the beginning. This study was published on the preprint server BioRχiv last year.

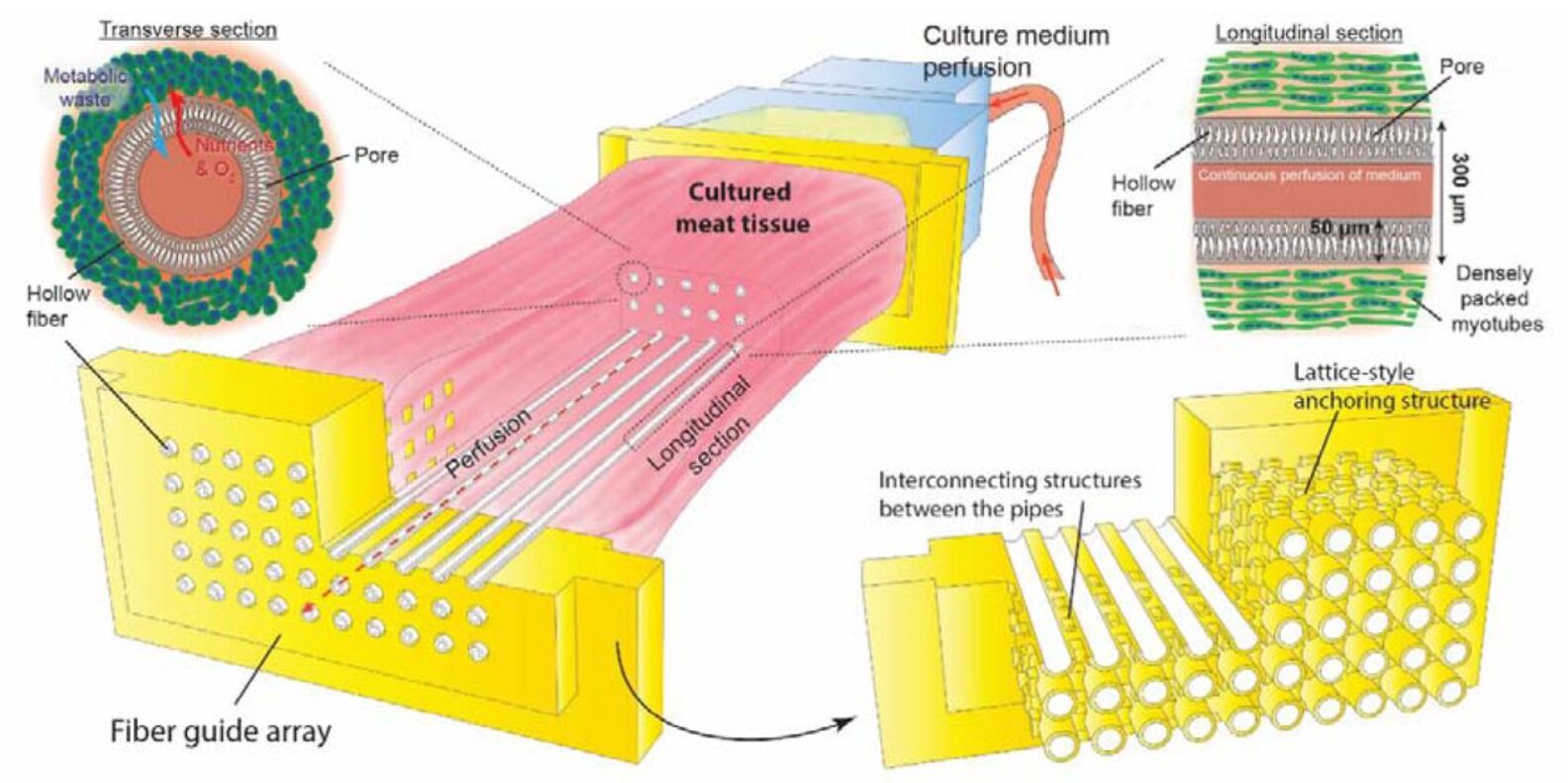

The Takeuchi Lab developed a perfusion culture device with artificial blood vessels using hollow fibers. Hollow fibers are thread-like materials with a hollow core, similar to macaroni or straws. The idea is to create tissue with multiple pathways equivalent to blood vessels from the start.

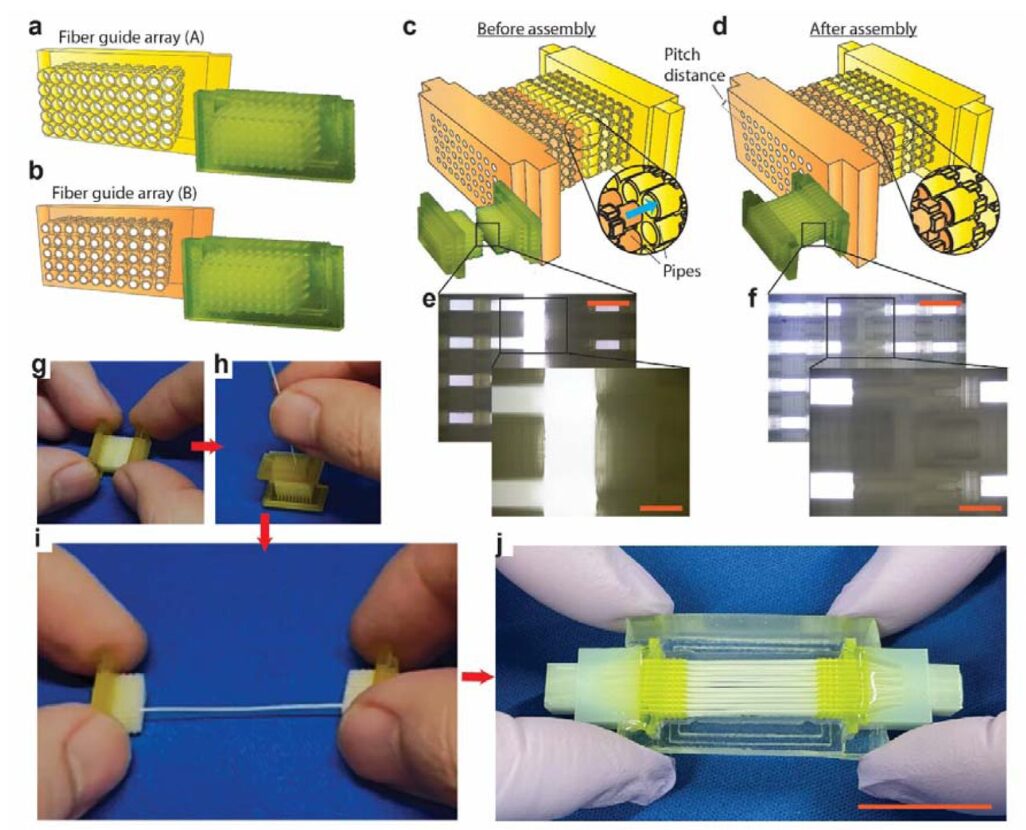

This device, called a hollow fiber bioreactor (HFB), has fine holes at both ends made with a 3D printer, through which the hollow fiber is threaded. The hollow fibers function like blood vessels, delivering nutrients and oxygen. One end of the hollow fiber is connected to the culture medium, while the other is attached to a suction pump.

Although it is called a hollow fiber bioreactor, it is not used to cultivate cells for growth. Instead, the goal is to create tissue using cells and hydrogel from the start and to mature the tissue within the device.

The Takeuchi Lab cultured primary chicken myoblasts using 50 hollow fibers. After nine days of perfusion culture, they obtained a small tissue fragment measuring 2cm x 1cm x 5mm (as shown in the image above).

They analyzed the tissue cultured under conditions with and without perfusion after removing the hollow fibers. Without perfusion, muscle fibers only formed in the peripheral area, and the center became necrotic. However, with perfusion, muscle fiber formation was observed even in the center.

In terms of texture and amino acid analysis, the perfused tissue was firmer and contained twice the amount of amino acids compared to the control group. Additionally, while the non-perfused tissue did not contract at all under electrical stimulation, the perfused tissue exhibited muscle contraction, according to Dr.Shima.

While the results of the hollow fiber bioreactor are promising for developing cultured steak, there is a challenge: to create centimeter-sized tissue, more than 1,000 hollow fibers must be used.

The Takeuchi Lab is currently working on developing a semi-automated system to place hollow fibers using an XYZ stage for scaling up the process.

Towards the Formation of Thicker Muscle Fiber Tissue

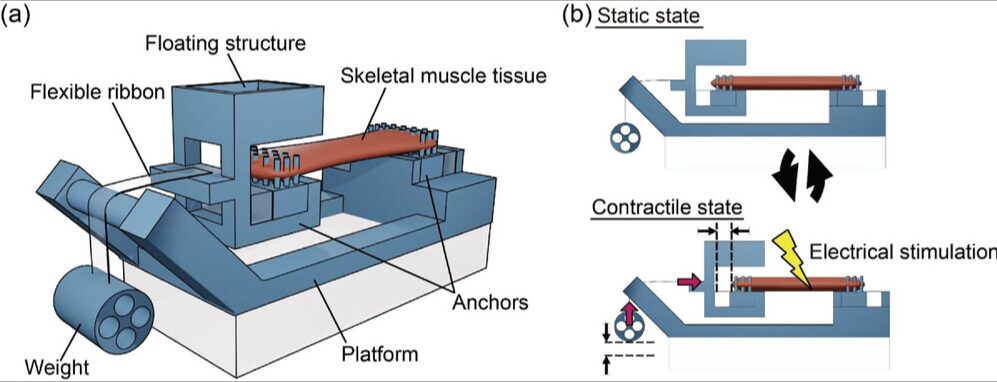

Dr.Shima also introduced the “weight training device” designed to create thicker muscle fibers. By making the muscle cells larger, it is thought that it may lead to improvements in the texture and taste of cultured steak.

This device causes muscle contraction when subjected to electrical stimulation, lifting a weight. It has been confirmed that this “muscle training” increases the diameter of muscle fibers by 30%.

Although they have not yet tested this with bovine muscle fibers, this system has the potential to thicken the muscle fibers of cultured tissues, improving the texture and flavor of cultured steak. A paper on this research was published on August 30 of this year.

Image Courtesy:The research lab of Shoji Takeuchi at the University of Tokyo