This article is an English translation of Foovo article, published with permission from Foovo.

A research group led by Professor Shoji Takeuchi at the University of Tokyo has successfully produced a thick piece (approximately 11 grams) of cultured chicken meat by using hollow fibers—tubular structures with a central cavity—to ensure uniform distribution of nutrients throughout the tissue.

The research findings are summarized in a paper titled “Scalable tissue biofabrication via perfusable hollow fiber arrays for cultivated meat applications,” published in Trends in Biotechnology on April 16, 2025.

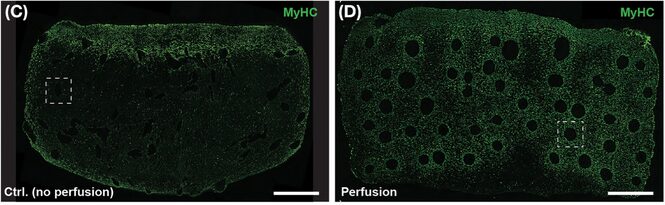

According to the press release, previous cultivated meat production methods relied on supplying nutrients from the outer surface of the tissue. This presented a challenge when creating thick tissues, as nutrients and oxygen could not adequately reach the core, resulting in cell necrosis. Such necrosis has been cited as a barrier to commercialization due to its impact on texture consistency and flavor components.

Previously, Professor Takeuchi’s lab, in collaboration with Nissin Foods Holdings, succeeded in producing a piece of cultured beef measuring 5.5 cm × 4 cm × 1.5 cm by stacking modular sheets composed of bovine myoblasts and collagen—a bottom-up approach.

In contrast, the latest study introduces a new top-down approach that mimics the vascular structure found in animal bodies. Instead of stacking modules, the tissue is formed with multiple pre-installed blood vessel-like structures using hollow fibers.

Hollow fibers refer to thread-like materials with a hollow core, resembling straws or macaroni.

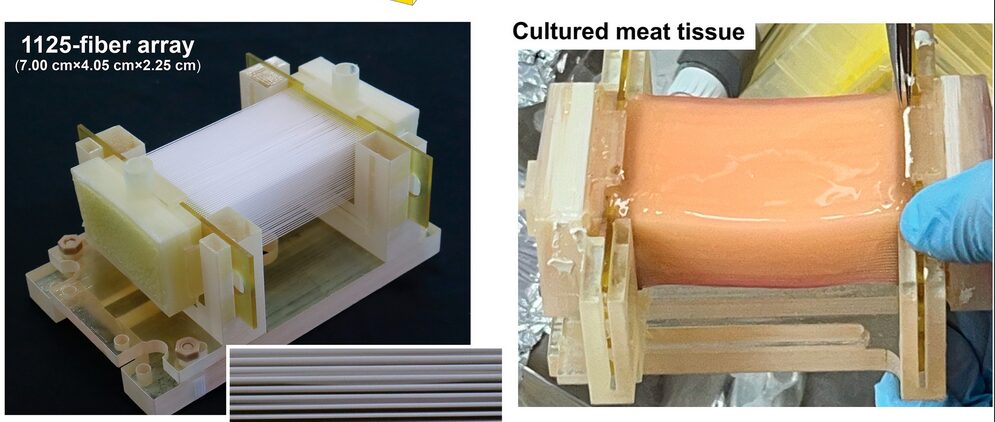

Professor Takeuchi and his team developed a proprietary culture device known as a hollow fiber bioreactor (HFB), in which multiple hollow fibers are aligned evenly and connected at both ends. One end is attached to a supply of culture medium, allowing efficient delivery of nutrients and oxygen throughout the tissue.

The hollow fibers are made of semipermeable membranes that allow only specific molecules—such as nutrients and oxygen—to pass through. This mechanism enables a gradual supply of these substances from inside the fibers to the surrounding cells. As a result, necrosis was suppressed even in the center of the tissue, improving chewiness (a key texture indicator) and potentially enhancing flavor.

Comparison images with and without perfusion (C and D, respectively) are presented in the paper.

The paper reports that the team first succeeded in producing centimeter-scale cultivated meat using 50 hollow fibers, confirming the effectiveness of perfusion culture in terms of morphology, functionality, and nutrient distribution.

The system was then scaled up using robotic automation to include 1,125 hollow fibers. This enabled the production of a thick cultured chicken sample weighing approximately 11 grams. Through this achievement, the research group demonstrated the feasibility of producing centimeter-scale cultivated meat using a hollow fiber bioreactor, as well as the scalability of the approach.

The space between the 1,125 hollow fibers was filled with a hydrogel containing chicken-derived fibroblasts (UMNSAH/DF-1), and perfusion culture was carried out over five days at a flow rate of 7.5 mL/min. After the hollow fibers were removed from the completed tissue, the final product weighed approximately 11.1 grams (see photo below).

The hollow fibers used in the study had diameters of approximately 0.3–0.35 mm and were precisely arranged at intervals of around 699 μm. This enabled uniform delivery of nutrients and oxygen throughout the cultured tissue, improving both cell distribution and muscle fiber alignment.

This research demonstrates the potential for a top-down approach—different from the conventional bottom-up, module-stacking methods—for the fabrication of whole-cut cultivated meat. It represents a significant technical advancement toward the automation and mass production of cultivated meat.

Use of hollow fiber bioreactors has also been observed overseas. One example is the UK-based company Cellular Agriculture, founded in 2016, which received funding from Innovate UK last year to explore the scalability of hollow fiber bioreactor technology.

Photo Credit:University of Tokyo