Photo by Ayumi Sato, Foovo.

At BioJapan 2025, held from October 8–10 at Pacifico Yokohama, multiple samples of cultivated meat were displayed, offering visitors a tangible look at this emerging technology.

The exhibits reflected significant progress among Japanese companies, featuring prototype development, utilization of byproducts, industry–academia–government collaborations, and proprietary cultivation technologies — all underscoring the steady advancement of Japan’s cultivated meat industry.

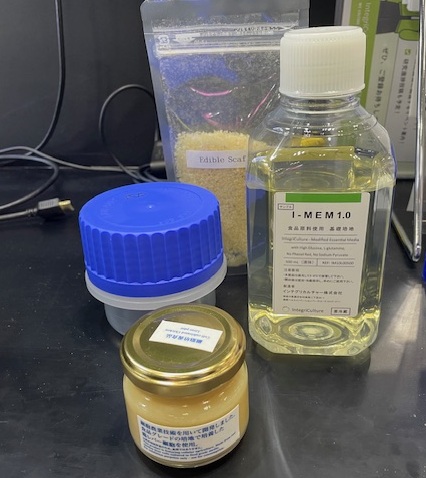

IntegriCulture has been accelerating the social implementation of cellular agriculture through initiatives such as the CulNet Consortium, launched in 2021, and the B2B marketplace “Ocatté Base”, which began operation last year.

At BioJapan, the company showcased a cultivated duck meat prototype.

According to Keita Tanaka of the Business Planning Division, “We now have a production system capable of one kilogram per week.”

The company is currently working on using natural mineral water and brewing byproducts in cell culture. By incorporating local water sources and byproducts into the production process, IntegriCulture aims to create regionally distinctive cultivated meat.

Tanaka added, “Ultimately, we want to install equipment in various regions so that production can take place locally, hoping to improve the image of cellular agriculture.”

While upcycling of byproducts is expanding in mycoprotein production using fungi such as koji, applications in the cultivated meat field remain limited. IntegriCulture’s challenge is therefore not only a step toward sustainable food production but also a potential model for regional revitalization, creating local industries and employment opportunities for younger generations.

At the NEDO booth, ZACROS, TOPPAN, and Shimadzu Corporation showcased cultivated beef produced through a 3D cell culture technology co-developed with Osaka University. The sample measured 7 cm × 3 cm × 1.5 cm, displaying fine marbling.

Since fiscal year 2023, the three companies have been advancing this technology under NEDO’s “Bio-Manufacturing Revolution Promotion Project”, scheduled to run through 2027. The exhibit represented the latest progress in their joint research.

The team has developed a process in which unique materials are added to the cells to create elongated fibers. By arranging muscle, fat, and blood fibers in desired positions, they can adjust the marbling of the meat. The group also developed food-grade scaffolds and achieved several-liter-scale cultivation using culture bags and bioreactors. They have now succeeded in scaling up to 100-liter cultures.

At the Expo 2025 Osaka, Kansai, which concluded on October 13, an even larger piece of cultivated beef was displayed, and in July, visitors were invited to experience the aroma of cooked cultivated beef at a dedicated event.

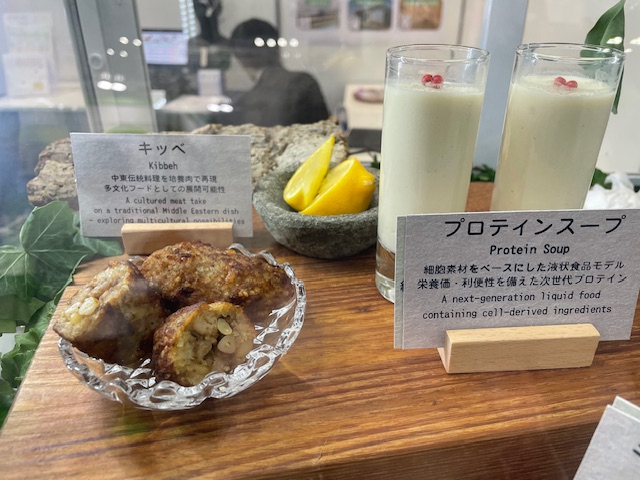

Organoid Farm presented multiple prototypes, including 100% cell-based raw cultivated beef, a 100% cell-based mini burger, a protein soup made from cell-derived ingredients, and “Kibbeh”, a Middle Eastern dish recreated using cultivated ingredients — showcasing the versatility and potential of the material.

In Organoid Farm’s process, bovine myoblasts are proliferated through scaffold-free suspension culture, followed by centrifugation.

While some startups use scaffolds to facilitate cell proliferation, Organoid Farm aims to achieve scalable, reproducible, and versatile production by eliminating the need for scaffolds. The company plans to open a pilot demonstration facility in 2027.

Organoid Farm is also participating in IntegriCulture’s Ocatté Base, and as of October 2, the bovine myoblasts produced by Organoid Farm became available for direct purchase through the platform’s e-commerce site.

Collectively, these exhibits illustrated that Japan’s cultivated food industry is steadily progressing toward social implementation. The next BioJapan is expected to reveal even more significant achievements.

This article is an English translation of a Foovo article, published with permission from Foovo.

You may also LIKE:

Japan’s Organoid Farm plans to open a pilot demonstration facility in 2027