From left: Nozomi Yamada, Yuki Hanyu, and Ikko Kawashima. Photo: Foovo (Ayumi Sato).

This article is an English translation of a Foovo article originally published on November 28, 2025, and is published with permission from Foovo.

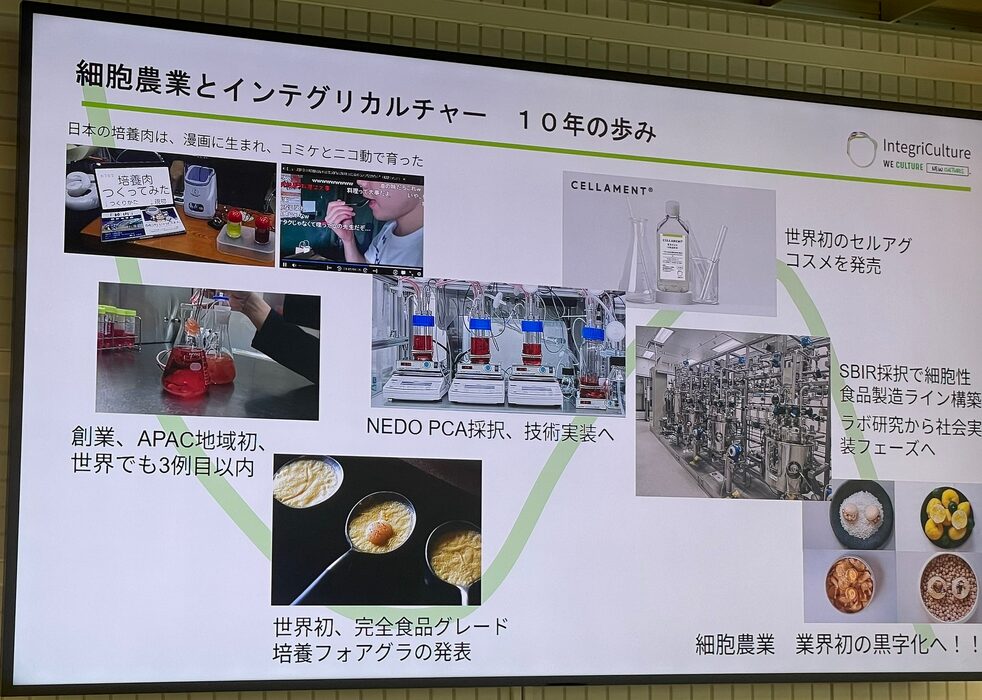

Integriculture, which aims to democratize cellular agriculture, has revealed that it is on the verge of achieving profitability.

At a business briefing held on the November 18th at the shared laboratory “LiSH” in Takanawa Gateway City, co-founder and CEO Yuki Hanyu stated, “We are approaching profitability ahead of the rest of the industry. With this fiscal year’s results, we are now almost certain that the business will stand on its own.”

According to COO Nozomi Yamada, current revenue is split evenly between the cosmetics sector and contract-based collaborative research.

With an IPO in sight, the company plans not only to launch cell-based foods domestically in 2027 but also to expand its proprietary technologies to additional sites beyond its current base at Shonan Health Innovation Park. In addition, Integriculture is broadening its efforts to develop regional revitalization models that link cellular agriculture with local resources.

As the so-called protein crisis is expected to emerge around 2030, Hanyu warned that “the food crisis has already begun in the form of rising prices.” He pointed out that increases in food prices—not limited to protein—could lead to social instability, and argued that cellular agriculture can not only support a sustainable food system but also become a new model for regional revitalization.

Toward a regional revitalization model through cellular agriculture

Integriculture’s move toward regional revitalization is built on years of accumulated progress in technological development and ecosystem building.

Founded in 2015, the company has focused on creating the foundational infrastructure needed to bring cellular agriculture into real-world applications.

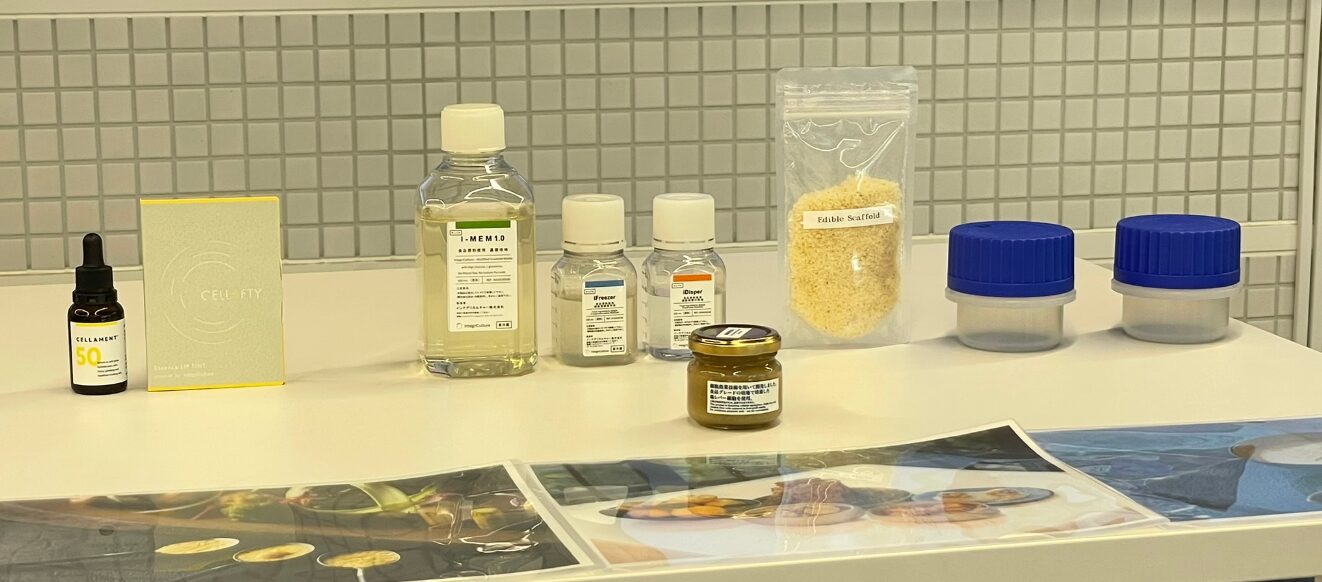

Its cross-industry solutions include the open innovation “CulNet Consortium,” which had 19 participating companies as of September 2025; the “CulNet Pipeline,” a contract-based collaborative research service that supports new market entrants; and “Ocatté Base,” a B2B marketplace that provides materials and expertise.

In 2019, Integriculture became the first company in the world to successfully produce fully food-grade cell-based foods using duck liver–derived cells.

Its material “Cellament,” derived from the supernatant of cultured egg cells, has been adopted by more than 10 companies, including Euglena, and is being implemented in the cosmetics sector. Following an initial sensory evaluation held in February 2023, the company conducted a second sensory evaluation this February.

Earlier this month, Integriculture announced that a joint research project on cell-based surimi conducted with Ichimasa Kamaboko and Maruha Nichiro has completed its production technology exploration phase and has moved on to the next stage of development.

Targeting monthly production of 320 kg by 2029

The proliferation of animal cells requires both nutritional components and blood-derived components.

From its inception, Integriculture has worked to replace all nutritional components with food-grade ingredients, and in 2023 it developed “I-MEM 2.0,” a basal medium composed entirely of food ingredients.

For blood-related components, rather than adding growth factors externally, the company built the “CulNet® system,” which mimics in vivo mechanisms by generating necessary factors internally within the device. This enables the entire cell culture process to be completed using only food-grade materials.

The company is currently producing cell-based foods at a scale of 10 kg per month and aims to deploy equipment capable of producing 320 kg per month by 2029. At the 10 kg scale, costs are approximately ¥30,000 (approximately USD 192) per 100 g, but scaling up to 320 kg is expected to reduce costs to around ¥3,000 (approximately USD 19.2) per 100 g.

Safety testing is also being conducted in parallel, and to date, no safety concerns have been identified.

Driving behavioral change through empathy rooted in regional identity

Photo: Foovo (Ayumi Sato)

The company’s next focus is regional revitalization through cellular agriculture. In addition to “safety and security” and “taste,” Integriculture is building new regionally driven cellular agriculture models centered on empathy with local food culture and characteristics.

The company has discovered that differences in the water used for cultivation affect the flavor of cells. When duck cells were cultured using water sourced from different regions across Japan, distinct flavor variations were observed. Much like sake, the “character of the water” was found to manifest as the “character of the cells.”

“The next industrial revolution begins locally”

Photo: Foovo (Ayumi Sato)

The company’s next focus is sake breweries.

Integriculture found that nutrients extracted from byproducts generated during sake brewing can be combined with local natural water to culture cells. This opens the possibility for experiential regional businesses in which breweries themselves produce “meat with unique character” and serve it to visitors.

Much like sake tastings, cellular agriculture could create a new regional attraction through “tasting cultivated meat produced by different breweries.”

Yamada commented, “By combining clean water, underutilized resources, and our technology, we want to create new industries rooted in each region and spark the next industrial revolution that begins locally.”

According to co-founder and CTO Ikko Kawashima, sake breweries have responded positively, drawn by the similarities between brewing and cell cultivation processes and by the potential for a new business foundation amid a shrinking sake market. The company is developing designs for microbrewery-style installations requiring approximately 30 square meters of space within breweries.

Integriculture has already partnered with Tsunan Sake Brewery in Niigata Prefecture. By integrating cellular agriculture into traditional Japanese industries, there is potential for a new form of manufacturing uniquely rooted in Japan.

This article is an English translation of a Foovo article originally published on November 28, 2025, and is published with permission from Foovo.

You may also LIKE:

Cultivated Meat Showcased at BioJapan 2025 —Japan’s Steady Progress Toward Commercialization

Japan’s Organoid Farm plans to open a pilot demonstration facility in 2027