Koji Labo, a certified spin-off from the University of Tsukuba, held its first tasting event featuring mycoprotein made from cultivated koji biomass on 22 June at the natural-foods restaurant Genkitei in Tokyo.

Through five different dishes, the event showcased the wide-ranging potential of fermentation-derived protein. Foovo joined the event and sampled the dishes.

Koji Biomass Can Become “Meat” and “Sauce”

The dish that left the strongest impression was the unseasoned “test koji meat.” Despite the lack of added flavourings, the ingredient itself delivered umami, and its texture had pleasant fibres reminiscent of real muscle.

Among the offerings, the chinjao-rosu-style stir-fry especially stood out. A slight springiness and bite brought it close to real meat; while not identical, it was convincingly tasty.

In contrast, a daikon salad used the same biomass as a substitute for canned tuna. Here the texture changed completely, with a firm chew comparable to thinly sliced meat. The experience suggested applications not only as tuna replacement but also for sliced meats or even offal-like products.

From a market-entry perspective, the most feasible dish seemed the hamburger steak. It combined 100 g of koji biomass with 200 g of ground meat, eliminating any off-notes in taste or texture and offering a realistic bridge product for mainstream consumers.

What I found particularly interesting was that we were able to taste and compare koji biomass made with different fermentation by-products—sake lees and shōchū lees. The koji “meat” produced with shōchū lees had a slightly firmer bite, and several other participants shared the same impression.

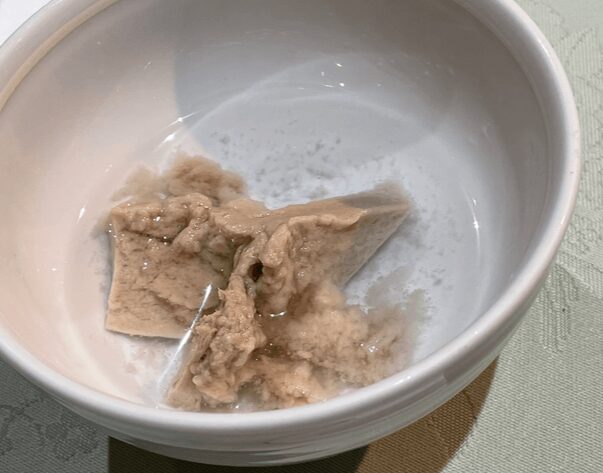

What Does Koji Biomass Look Like?

After cultivation, the biomass is harvested and frozen. When broken apart, it exhibits fibres that tear like washi paper.

Surprisingly, it disperses easily in water, feeling like tissue dissolving.

Leveraging that property, Koji Labo served a koji-based bagna càuda. Blended with soy milk, miso, shio-koji and garlic, the sauce was silky, showing the biomass fully integrated. This suggests possibilities for high-protein smoothies, yogurts, ice creams and more.

“Saving the Planet with Koji” – Koji Labo’s Vision

Under the slogan “Save the Earth with Koji,” Koji Labo aims to provide innovative alternative meats that are delicious and enable circular use of resources. The idea began at the University of Tsukuba, where Daisuke Hagiwara envisioned repurposing cultivated koji biomass as alternative meat. In December 2024 he founded Koji Labo, using food by-products such as sake and shōchū lees as growth media.

Koji Labo’s biomass offers distinctive umami, a soft mouthfeel and the rare ability to disperse in water. Besides protein it contains dietary fibre, opening applications from minced‐meat analogues and sauces to thin-sliced “meat” that exploits its natural strands. The tasting event vividly demonstrated this range.

Initially focusing on sake lees, the team began up-cycling shōchū lees through a JST OPERA joint project with Sanwa Shurui. “Since the taste varies depending on the type of sake lees, we would like to establish this as our own technology by drawing out the possibilities of making it tasty in the culture process.,” Hagiwara explained.

Continuing joint research with Tsukuba University, the company raised about ¥1.7 million via Academist crowdfunding last year, which helped fund this tasting.

The main technical hurdle is reproducing textures rather than flavour. During prototyping the focus is on cultivation, with limited post-processing; going forward Koji Labo plans to refine processing in collaboration with companies and restaurants.

Looking ahead, two issues stand out: (1) cutting costs for mass production, and (2) making products tasty enough for rapid, broad adoption. Scaling technology can address cost, but market development and demand forecasting also matter. Palatability will be improved through external partnerships.

Environmental impact is another core theme. Rather than focusing solely on CO₂ reduction, Koji Labo seeks to reuse fermentation by-products, circulating under-utilized resources and boosting overall efficiency. Even the spent culture broth might be turned into stock: participants suggested using it as dashi, and Hagiwara expressed interest in collaborating with food makers to make that happen.

Koji Labo also plans to enhance amino-acid balance, vitamin levels and functional compounds such as GABA; the biomass already scores 100 on amino-acid score.

This article is an English translation of a Foovo article, published with permission from Foovo.