Fermelanta, a Japanese company that uses synthetic biology to ferment and produce rare, useful components derived from nature, completed a Series A funding round of ¥2 billion at the end of last month.

This brings the company’s total funding raised to ¥4.8 billion.

The funds raised will be used to expand the development pipeline and scale up from lab to pilot scale. Furthermore, through a Contract Development and Manufacturing Organization (CDMO), the company will advance sample prototyping and mass production validation for its development pipeline.

Fermelanta was established in 2022 as a venture company originating from Ishikawa Prefectural University. It is engaged in bio-manufacturing using synthetic biology, producing rare, useful components derived from natural sources such as plants through microbial fermentation. Its development targets span pharmaceuticals, cosmetics, functional ingredients, fragrances, pesticides, feed additives, and more.

The research team holds the distinction of being the first in the world to successfully produce alkaloids—plant secondary metabolites—via microbial fermentation in 2008. (Alkaloids include morphine and codeine, used in pharmaceuticals).

Last year, the company was selected for the Ministry of Agriculture, Forestry and Fisheries’ Small and Medium Enterprise Innovation Creation Promotion Project. It is currently constructing a pilot plant equipped with a 3,000-liter bioreactor, scheduled for completion in May next year.

“Bio-manufacturing” positioned as a national strategy

Bio-manufacturing refers to the production of substances using cells from microorganisms, plants, and animals. This technology is utilized across various industrial sectors, including pharmaceuticals, cosmetics, biofuels, plastic feedstocks, and food.

According to the government’s “Bioeconomy Strategy,” within the context of food tech, this includes precision fermentation, where microorganisms act as “mini factories” to generate useful substances, and cultivated foods (such as cultivated meat), which involve proliferating the cells themselves (PDF p8).

The Bioeconomy Strategy sets a market size target of ¥53.3 trillion for 2030 and aims to expand public and private investment to ¥3 trillion annually by 2030 (pdf p17).

In fiscal 2022, a large-scale budget totaling ¥1 trillion was allocated, including the Green Innovation Fund Project led by the Ministry of Economy, Trade and Industry and the Bio-Manufacturing Revolution Promotion Project, and it was launched as a national project (p3).

Microbial Fermentation for a Stable Supply of Rare Components

Fermelanta focuses on synthetic biology, a notable field within bio-manufacturing.

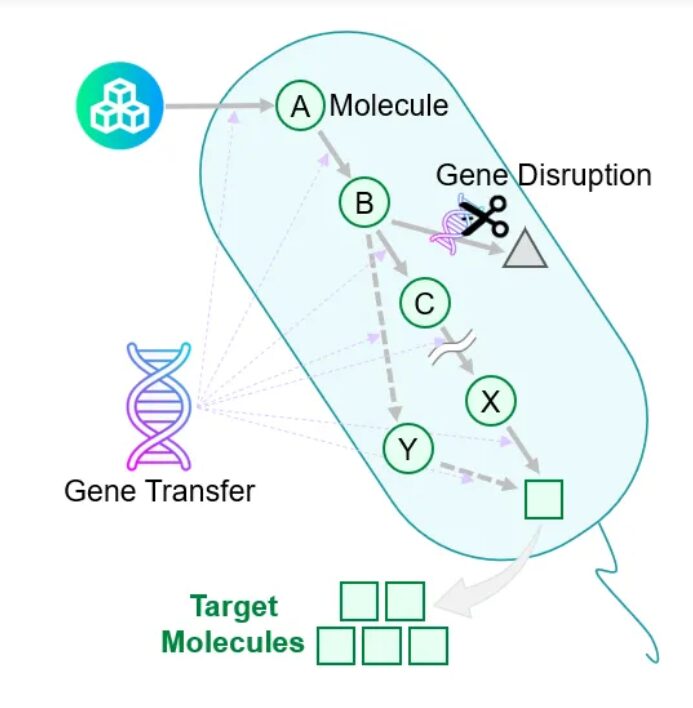

While conventional applied microbiology and genetic engineering focus on “discovering and modifying” functions found in nature, synthetic biology is characterized by its ability to “create new functions that do not exist in nature.” Building on this technology, the company is developing systems that use microorganisms as factories to produce a wide range of compounds—from small molecules to polymers—cost-effectively, regardless of field or structure.

The company successfully constructed a modified biosynthetic pathway within E. coli and established a multi-step gene introduction technology capable of introducing and expressing over 20 foreign genes into a single bacterial cell.

Furthermore, it has developed proprietary technologies such as optimization techniques for gene expression balance to enhance target substance production efficiency and the creation of protein overproduction-tolerant strains (strains that are less prone to growth arrest even when producing large amounts of protein). By combining these foundational technologies, the company constructs biosynthetic pathways of over 20 steps within cells.

As announced in June 2023, this enables fermentation production of target substances at the gram scale per liter of culture medium.

The current development targets have expanded from the initial single pharmaceutical raw material theme at the company’s founding to over 10 themes.

For some compounds, yields below the unit price of existing market products have been achieved at the lab scale, and highly reproducible production demonstrations have been realized at the bench scale. The latest announcement states that production of tens of grams per batch has been achieved. Going forward, the company aims to scale up to tens to hundreds of kilograms per batch through partnerships with CDMOs.

Fermelanta opened its Tokyo office in August this year, complete with a dedicated lab. In April, it established a business development hub in the United States and plans to advance business development in European markets, including France.

With its synthetic biology, Fermelanta is targeting areas where compounds are rare and useful but difficult to source stably through conventional methods like plant extraction.

The newly invested Keio Innovation Initiative also evaluated this as an “innovative method to replace existing manufacturing methods that are high-cost, low-purity, and environmentally burdensome,” and has high expectations for the company’s technology to “pave the way for a new industrial model.”

With its sights set on North America and Europe, the company’s efforts appear poised to become a model case of Japanese bio-manufacturing challenging the international market.

This article is an English translation of a Foovo article, published with permission from Foovo.