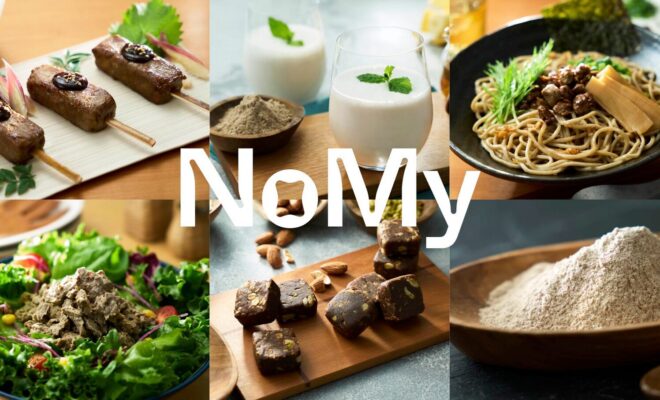

Source: NoMy Japan

NoMy Japan announced on the 10th that it has started a joint evaluation with Kagome to explore the potential for developing products utilizing mycoprotein ingredients.

In April of last year, the company announced a strategic partnership with Nitten (Nippon Beet Sugar Manufacturing) to utilize sugar production byproducts. This collaboration with Kagome marks its second partnership with a Japanese food manufacturer.

NoMy Japan is the Japanese subsidiary of Norwegian Mycelium (NoMy), established in Norway, and was founded in January 2024. In May of this year, it raised €1.25 million (approximately ¥200 million at the time) through Norwegian Mycelium from investors including Nitten.

When filamentous fungi such as koji mold are cultivated in nutrient media, a fibrous biomass is formed—this is mycoprotein. A well-known example is the UK brand Quorn.

Mycoprotein, obtained through the cultivation of fungi, is noted for its high protein and dietary fiber content, low fat, and meat-like texture.

NoMy develops mycoprotein using waste materials and mycelium.

Under the collaboration with Kagome, the two companies will evaluate the technical feasibility, sensory characteristics, and commercialization potential of prototype products. NoMy Japan plans to prioritize collaborations with Japanese companies and focus on a pilot project in 2026.

Since 2023, Kagome has been working at its Fujimi plant to utilize plant-based residues generated during the production of beverages such as tomato juice and vegetable juice as renewable energy sources.

While the specific details of the collaboration have not been disclosed, it is possible that plant-based residues from Kagome’s production—such as tomato pomace—could be evaluated as substrates for fungal fermentation. (According to international media, NoMy uses filamentous fungi.)

Sumarriva-Bustinza et al. (2025) report that converting agricultural byproducts such as tomato pomace, sugarcane bagasse, and wheat bran into mycoprotein through fungal fermentation is a promising approach for sustainable food systems and food security, given its resource efficiency and emission-reduction potential.

Domestic efforts to develop mycoprotein have been gaining momentum in Japan.

Koji Labo, a startup from the University of Tsukuba, is developing mycoprotein using koji. In June this year, it held a tasting event for crowdfunding supporters and the general public.

AgroLudens announced partnerships in June 2024 with Otafuku Jozo and Otafuku Sauce. It has launched several consumer products made with its mycoprotein “Comeat,” developed from rice protein and koji mold, via its official online store “Haccome.” Since October 1, a selection of these products has been available at “TIB SHOP,” a pop-up space for consumer-goods startups, until the end of November.

Yaegaki Biotechnology, which has been partnering with the Dutch research institute NIZO since 2023, announced in July 2025 that during a visit from Dutch Minister Jean Lemeyne and others, it showcased and offered tastings of alternative-meat prototypes made with mycoprotein.

Nippon Ham also announced in June 2023 that it was developing food products using koji itself as an ingredient.

Overseas, major companies such as Cargill with UK-based ENOUGH, zur Mühlen Group (ZMG) with Germany’s Nosh.bio, and a leading South American meat company (unnamed) with the U.S. firm The Better Meat Co. are forming partnerships with mycoprotein developers.

Although domestic mycoprotein development is gaining traction, Foovo’s June 2024 survey found that more than 50 mycoprotein companies have already emerged worldwide, while Japan still has relatively few players.

Mycoprotein is attracting attention for its high nutritional value, low environmental impact, and potential to upcycle industrial byproducts. Companies with expertise in byproduct utilization, fermentation infrastructure, and food processing have significant opportunities to leverage their strengths in this field.

Looking ahead, the ecosystem is expected to expand—particularly among companies with agricultural or brewing byproducts—and further participation from domestic players is anticipated.

This article is an English translation of a Foovo article, published with permission from Foovo.