Photo: Foovo (Ayumi Sato)

Japanese cultivated meat startup Diverse Farm is planning to expand its manufacturing technology overseas through a B2B model for early commercialization, as Japan moves forward with establishing guidelines for cultivated foods.

The company is developing 100% cell-based cultivated chicken and aims to first provide its technology to Singapore and Australia, where regulatory frameworks for sale and production are already in place.

We spoke with Jiro Ono, co-founder and CEO of Diverse Farm, about the company’s business strategy during the “Japan Cell-Ag-Ready Dialogue 2025,” an international conference on the food use of cultured cells held in Tokyo on November 13–14.

The Core Technology: “Net-Mold Method”

Diverse Farm was founded in 2020 by Ono—who previously founded TissueByNet, a regenerative-medicine startup developing artificial skin—and Masaharu Shimamura, owner-chef of the Osaka kaiseki restaurant Unkaku.

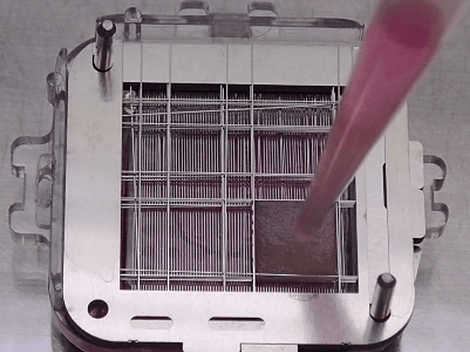

The company is developing cultivated chicken using TissueByNet’s “Net-Mold Method” as its core technology.

In the Net-Mold Method, a mass of cells is poured into a mold fitted with layered nets. As the cells become caught on the nets and are cultured in that state, the cells proliferate and bind together, forming a large mass. Finally, by pulling out a comb-shaped mold, a piece of cultivated meat composed of 100% cells is produced. The process does not require any binding agents to connect the cells—one of its defining features.

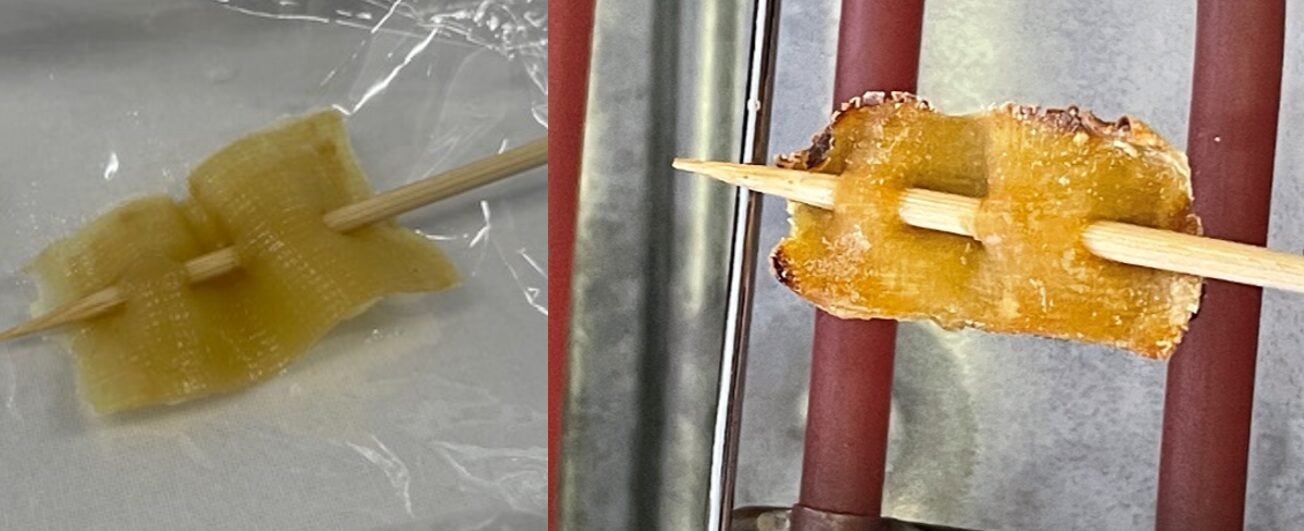

Left: Foovo / Right: Courtesy of Jiro Ono

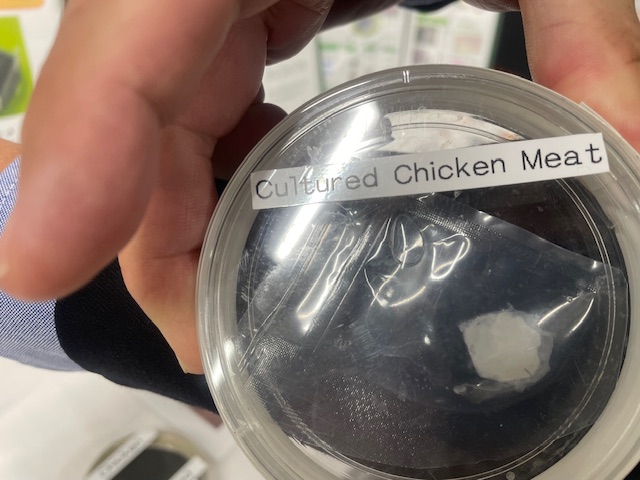

The company currently uses a 5 cm × 5 cm net mold. At the event, it exhibited a prototype made by stacking four 1-mm-thick sheets of cultivated chicken. When touched, the sample had a soft and supple elasticity.

Prioritizing the Japanese Market While Pursuing Overseas B2B Expansion

In Japan, guidelines for the sale and production of cell-based foods are not yet established, making commercialization difficult to foresee.

For this reason, while the company considers the Japanese market its top priority, it plans to first expand its Net-Mold technology through B2B partnerships in Singapore and Australia, where regulatory systems for sales are already in place. The concept is to leverage each partner’s existing cell lines and provide a package of technologies that enable cells to remain alive while being assembled into tissue.

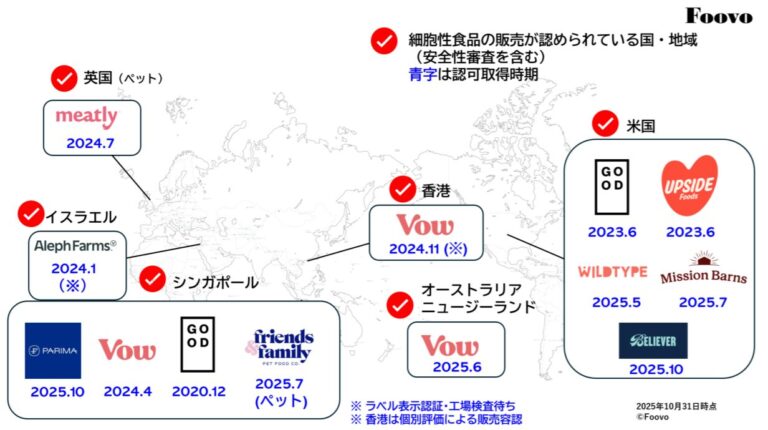

To date, Singapore has approved cultivated-meat sales for three companies—GOOD Meat, Vow, and PARIMA—while Australia and New Zealand have granted approval to Vow.

Having previously worked in the semiconductor and automotive industries, Ono emphasizes that the key to promoting cellular foods is a strategy of “starting small and scaling up.”

Following the example of Tesla, which entered the market with high-end vehicles before reaching mass consumers, he explains that offering cultivated chicken first as a premium experience valued around JPY100,000 at high-end restaurants such as kaiseki restaurants—and building a small-scale supply chain early—is critical. Expansion to mainstream restaurants and supermarkets would follow.

“Taking this approach also allows regulators to update the guidelines while observing the situation, which ultimately accelerates market development,” Ono said.

A Future of “On-Farm Cultivation Facilities” Coexisting with Poultry Farming

In 2022, poultry producer Masanori Abe joined the team, helping to shape a vision in which cultivated meat becomes a new option within animal agriculture. In May 2025, the company relocated its headquarters and research facilities to Hiki District, Saitama Prefecture, securing a space where small-scale livestock can be kept.

Diverse Farm envisions a world in which cultivated-meat facilities exist “inside the farm,” much like a winery standing beside a vineyard.

The company aims to offer farmers a manufacturing package—priced at JPY 5 to 10 million—that enables “convenience-store-sized” production of cellular foods. This would allow farmers to produce cultivated versions of their own branded poultry. In the poultry industry, which is vulnerable to external factors such as avian influenza, cultivated meat could function as a solution that supplements farmers’ livelihoods and provides a form of risk hedging.

Meanwhile, Japan does not allow public tasting events of cultivated foods, creating a major hurdle in expanding public interest and understanding. At present, only a few companies are conducting limited sensory evaluations with restricted participants. Sales at the Expo 2025 Osaka did not materialize.

Globally, tasting opportunities have become widespread, and safety verification has reached a certain level. Under the current situation in Japan—where tasting opportunities are scarce—broader adoption is difficult, and the lack of guidelines also affects plans for factory construction and capital investment.

Without a clear commercialization roadmap, investment will not be made. The company’s focus on overseas expansion reflects the reality that it cannot wait for Japan’s domestic regulatory development.

“I hear that Korea has created special zones where cultivated-meat tastings and other activities are possible under limited conditions. Japan could also take such an approach—starting small and growing bigger,” said Ono.

This article is an English translation of a Foovo article, published with permission from Foovo.